The product

The Wells extend the life of the temperature sensors, protecting them from flow effects, pressure and corrosion allowing the maintenance or replacement of the element without the need to stop the process.

Are widely used in energy industries, pharmaceutical and petrochemical products and in a variety of applications in process controls.

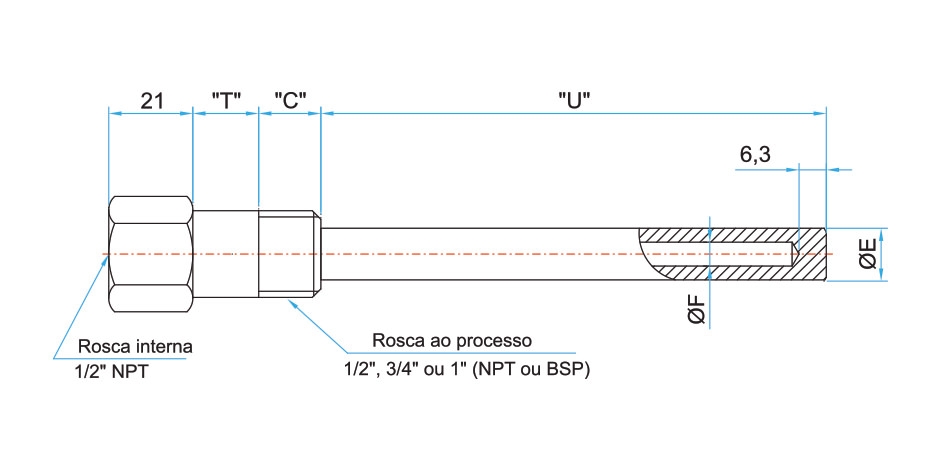

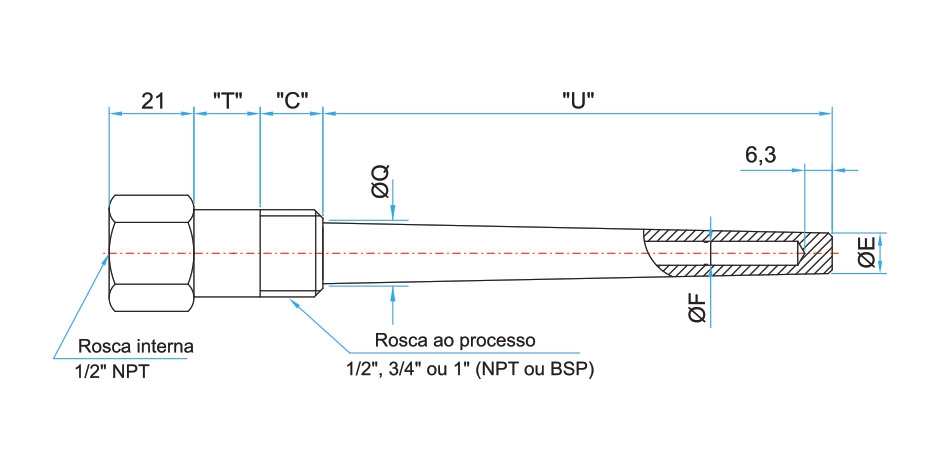

Are build from solid bar and machined internally and externally and are divided into two groups: threaded and flanges, straight or conical shaft.

To specify the protection wells, observe the correct material specification, installation environment, insertion length, response time, flow velocity and temperature.

The following wells are the most common in industrial applications, other types, materials and standards can be provided, for instance: wells for welding, probes with reduced peak, wells in Hastelloy, monel, titanium, Teflon coated, flanges in JIS, DIN, etc, standards. For more information, see our sales department.

Explore the complete list of Thermocouples from Alutal Temperature

Learn more about what a thermocouple is and its importance in the industry