The product

Thermal mass flow meter technology

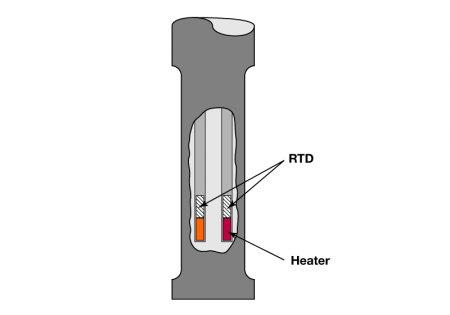

Thermal flow meters are primarily used in air and gas flow measurement applications. The meters consist of a transmitter and probe with temperature sensors (RTDs) located in the pins at the bottom of the probe. One sensor measures the process temperature and the other sensor is heated to a specific temperature above this. As the flow rate increases, heat gets taken away from the heated sensor in the form of convective heat transfer.

Features

- Direct mass flow measurement of air and gas

- Excellent low flow sensitivity with high turndown (rangeability)

- Process temperatures to +400 °F (+200 °C)

- Rotatable housing

- FM / FMc / ATEX / IEC approvals

- Resettable and non-resettable totalizers

- Calibration verification in the field

Options

- Pulse and second mA output for temperature

- Plug in display with keypad

- HART® / Foundation fieldbus™ / AMS® / PACTware™ communications

- Remote electronics

- Hot tap retractable probe

Operating principle

THERMATEL Model TA2 mass flow transmitter measures mass flow by detecting heat dissipation from a heated surface. The sensor contains two mass balanced elements with precision matched RTDs. The reference sensor measures the process temperature (up to +400° F [+200° C]); the second RTD measures the temperature of the heated sensor. The power to the heater is varied to maintain a constant temperature difference above the reference temperature.

There is an inherent non-linear relationship between power and mass flow. The microprocessor in the TA2 compares the power against the calibration curve and converts the power requirements to the mass flow rate. Temperature is also measured to provide temperature compensation of the mass flow over the operating range of the instrument.

Approvals

| ATEX | Ex d, Ex d+ib |

| CCOE | Ex d |

| cFMus | XP, NI |

| EAC (GOST) | Ex d, Metrology |

| IEC | Ex d |

| Inmetro | Ex d |

| Korea | Ex d |

| SIL | SIL 1 (1oo1) |

Other approvals are available. Consult factory for more details.

solicitar orcamento