The product

External cage switches technology

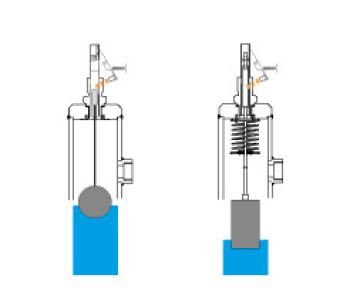

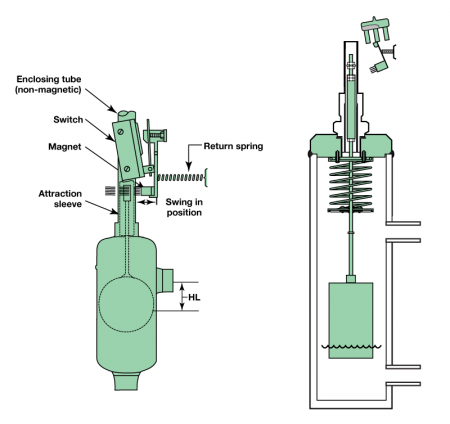

A permanent magnet is attached to a pivoted switch actuator. As the float/displacer rises following the liquid level, it raises the attraction sleeve into the field of the magnet, which then snaps against the non-magnetic enclosing tube, actuating the switch. The enclosing tube provides a static pressure boundary between the switch mechanism and the process. On a falling level, the float/displacer deactivates the switch

Features

- Fabricated carbon steel cages

- Model B74 available with 304 or 316 stainless steel cages as standard

- Inconel displacer spring and stainless steel trim

- Stainless steel displacers

- Sealed or flanged cages

- Pressures to 5000 psig (345 bar)

- Temperatures to +750 °F (+400 °C)

- Specific gravity as low as 0.40

Options

- Special levels/body extensions

- 316 and 304 stainless steel chambers

- NACE construction

- Gold switch contacts

- Interface detection

- Vent and drain connections

Operating principle

Liquid level movement changes the buoyancy force on a displacer suspended from a range spring. The force change on the spring causes it to extend or compress, moving an attraction sleeve into or out of the field of the switch magnet, actuating the switch

Approvals

| ATEX | Ex d, Ex ia |

| CCOE | Ex d |

| CSA | XP |

| FM | XP |

| EAC (GOST) | Ex d, Ex ia |

| IEC | Ex d, Ex ia |

| Inmetro | Ex d |

| Korea | Ex d |

| NEPSI | Ex d |

| SIL | SIL 2 (1oo1) |

Other approvals are available. Consult factory for more details.

request quote