The product

External cage switches technology

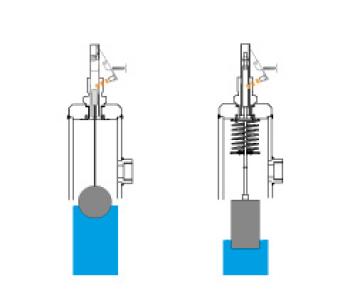

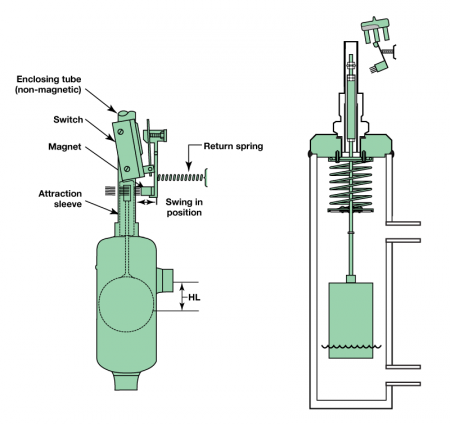

A permanent magnet is attached to a pivoted switch actuator. As the float/displacer rises following the liquid level, it raises the attraction sleeve into the field of the magnet, which then snaps against the non-magnetic enclosing tube, actuating the switch. The enclosing tube provides a static pressure boundary between the switch mechanism and the process. On a falling level, the float/displacer deactivates the switch

Features

- Carbon steel or stainless steel welded float chamber

- Service pressures up to 2240 psig (154 bar)

- Process temperatures up to +1000 °F (+538 °C)

- Specific gravity ratings as low as 0.32

- Available switch styles including dry contact, hermetically sealed and pneumatic

- ingle or multiple switch mechanisms available

- Optional high temperature insulation available

- Choice of switch mechanism: ? Dry contact ? Hermetically sealed ? Pneumatic

- hoice of switch mechanism enclosure: ? TYPE 4X/7/9 Class I, Div. 1, Groups B, C & D, polymer coated aluminum ? NEMA 1, carbon steel for pneumatics

- Choice of tank connection: ? 1″, 1½” or 2″ NPT ? 1″, 1½” or 2″ flanged side/side ? 1″, 1½” or 2″ flanged side/bottom ? 1″, 1½” or 2″ socket welds

Options

- Interface calibration

- Extreme temperature modifications

- Customized installation dimensions

- Customized exterior surface preparation and finish

- Customized actuation levels

- Vent and drain connections

Operating principle

The buoyancy force of a process liquid on the float causes the float to ride on the liquid surface. The movement of the float with the liquid level moves an attraction sleeve into the field of the switch magnet, pulling the magnet toward the sleeve and actuating the switch

Approvals

| ATEX | Ex d, Ex ia |

| CCOE | Ex d |

| CSA | XP |

| FM | XP |

| EAC (GOST) | Ex d, Ex ia |

| IEC | Ex d, Ex ia |

| Inmetro | Ex d |

| Korea | Ex d |

| NEPSI | Ex d |

| SIL | SIL 2 (1oo1) |

Other approvals are available. Consult factory for more details.

request quote