The product

he ALUF Series angular K-Type thermocouple is a permanent immersion temperature sensor specifically engineered for non-ferrous metal casting, especially molten aluminum. Designed to deliver precise, stable, and safe measurements, the ALUF model combines advanced technology, durability, and high resistance to extreme operating conditions, ensuring greater control and productivity in demanding foundry environments.

Importance and Benefits

In metal casting applications, the accurate measurement of molten metal temperature is a critical factor for product quality and process efficiency. The ALUF Series Thermocouple was developed to address key challenges in the metallurgical industry such as:

- Premature sensor wear caused by direct contact with molten aluminum

- Signal instability leading to compromised thermal control

- High costs associated with frequent equipment replacement

- Unexpected downtime due to failures in conventional sensors

With its angular K-Type construction and high-performance protective materials, the ALUF delivers extended service life, superior thermal stability, and reliable measurements even in harsh industrial environments.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Angular K-Type Thermocouple – ALUF Series |

| External Protection | NOD – Pearlitic Ductile Iron / SIC – Silicon Carbide / NIT – Silicon Nitride |

| Available Diameters | 20 mm, 22 mm, 24 mm, 30 mm, 40 mm, and 45 mm |

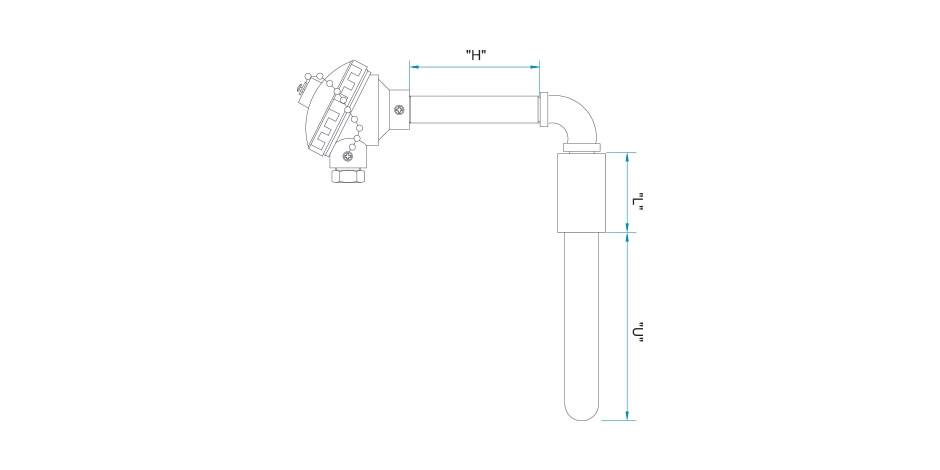

| Lengths | “L” (mm) – specify / “H” (mm) – specify / “U” (mm) – specify |

| Optional Features | RBC Calibration Certificate / RBC 3-Point Certificate |

Advantages of Using an Alutal Thermocouple in Foundry Processes

- Extended lifespan in direct contact with molten aluminum

- High precision and stability in continuous measurements

- Resistance to thermal shock and aggressive atmospheres

- Reduced maintenance costs and downtime

- Flexible configurations for different furnaces and processes

Applications and Industries Served:

The ALUF Series Thermocouple is ideal for foundry and heat-treatment processes of non-ferrous metals, especially aluminum and its alloys. It can be applied in:

- Aluminum melting and dosing furnaces

- Ingot casting and molding lines

- Temperature control in troughs and ladles

- Monitoring of automated metallurgical processes

Industries served:

- Foundry and metallurgical industry

- Automotive and metal component manufacturers

- Aerospace and automotive sectors

- Aluminum recycling industry

- Special alloy production

Custom Solutions by Alutal

Alutal Temperature offers customized solutions to maximize sensor performance in foundry processes, including:

- Anti-coating protective layers to prevent aluminum adhesion

- Custom-machined protective sheaths

- Metal–ceramic tubes with high mechanical and thermal resistance

These solutions increase durability, safety, and reliability in temperature measurement, reducing total operational costs.

Contact Alutal for the Ideal Solution

Every metal casting application has specific requirements. For this reason, Alutal Temperature develops custom thermocouples with materials and configurations tailored to each process.

Whether your goal is to optimize thermal control, reduce production stops, or increase sensor lifespan, our technical team will recommend the best solution for your operation.

Request a quote or speak to a specialist to discover how the ALUF Series Thermocouple can increase efficiency in your foundry.

Explore More

Explore the complete list of Thermocouples from Alutal Temperature

Learn more about what a thermocouple is and its importance in the industry