The product

The sensors with connection pot TRS11 Series (without head) are most suitable for brewing tanks and other cold drinks because of the need to use insulating against moisture. Thus the cable length must be specified in the order.

printhead assembly with sensors moisture can condense within the housing, leading to unstable and incorrect measurements.

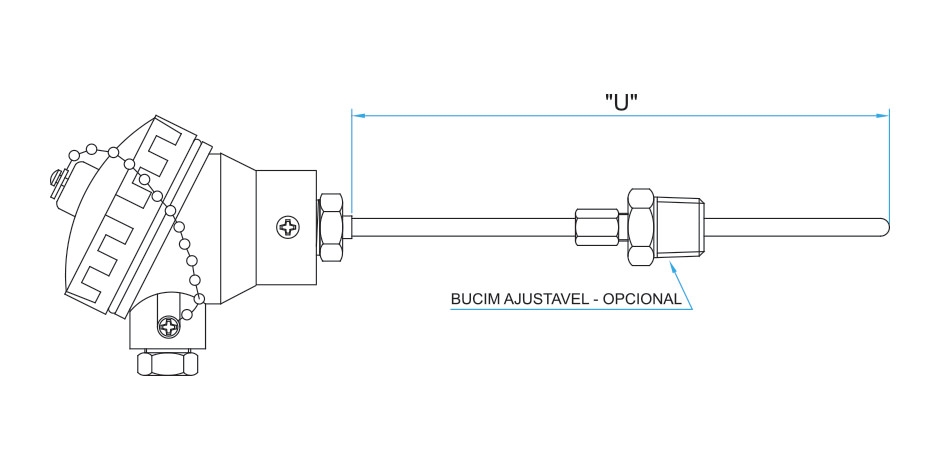

Sensors TRS13 Series (with large head) have a possibility Temperature Transmitters installation on their heads. Note that the temperature sensor head is not used for condensation environments, since the sensor may suffer from interference from environmental moisture that is installed.

WHY ARE USED TEMPERATURE TRANSMITTERS?

Temperature Transmitters are by definition electronic devices that convert the signal from the temperature sensors and convert an analog signal that is transmitted to the reading instrument. But why its use?

We list a few reasons below:

- Distance and Cost – A temperature transmitter has no physical limit of distance between the sensor and instrument, since the signal thermocouple / RTD is amplified and converted into electric current (4 mA ~ 20). In the case of thermocouples and resistance thermometers, even with the use of appropriate cables and special this threshold is related 200 to 300 meters, depending on the characteristic of the sensor and installation. The instrumentation cabling costs for retransmission are also typically smaller than the cost of a thermocouple cable.

- Intelligent Sensor – Sensors with communication with HART protocol, Modbus and Profibus ® may have special features, such as Auto Checking, maintaining the read value and alarm in case of rupture of the sensor, among others.

- Signal Universality – A temperature transmitter converts the sensor signal to universal signals Instrumentation. As there are many types of temperature sensors, thermocouples and resistance thermometers, the possibility of flexible sensor x instrument in a large loop is much higher.

Explore the complete list of Thermocouples from Alutal Temperature

Learn more about what a thermocouple is and its importance in the industry