What is a thermocouple? What is its importance in industry?

- Temperature definition

- Termopar, afinal o que é?

- Efeito Seebeck

- Tipos de Termopar

- Qual a diferença entre termopar e termorresistência?

- Conheça as 5 principais vantagens do Termopar sobre a Termorresistencia (RTD)

- Como escolher o sensor de temperatura correto?

- Importancia da calibração dos sensores de temperatura

- Descubra quanto custa 1°C de variação em combustível no seu processo

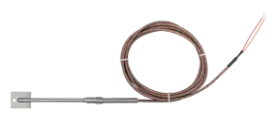

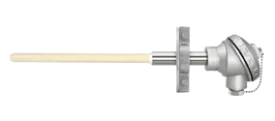

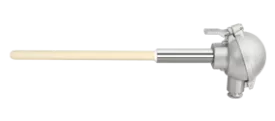

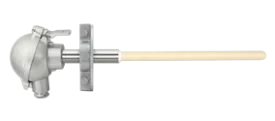

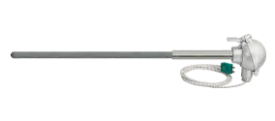

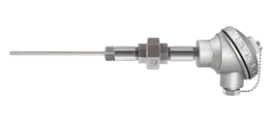

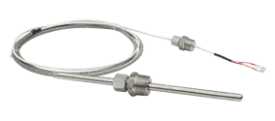

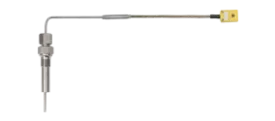

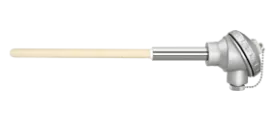

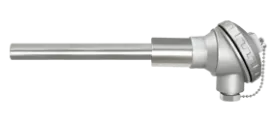

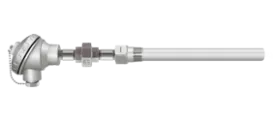

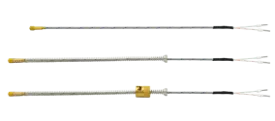

- Termopares fabricados pela Alutal

- Dúvidas frequentes

- Learn more about Thermocouples and Industrial Thermometry

Temperature definition

Temperature has always been very important to humanity. It has been one of the pillars of our evolution, contributing to safety, survival and even well-being. Nowadays, it has a profound impact on our daily lives, whether in measuring ambient temperature, body temperature, electrical and electronic equipment temperature, combustion engine temperature and principalmente em processos industriais.

We can conceptualize temperature as the degree of thermal agitation of the molecules that make up substances, being the physical quantity that allows the internal evaluation of a body, the second most used in the world, second only to time.

All modern industrial processes at some point in the production chain benefit from temperature measurement and control, thus providing the control required by current legislation.

There are 3 common ways to refer to temperature measurement:

- Thermometry: medição de temperatura

- Pirometria: medição de altas temperaturas

- Criometria: medição de baixas temperaturas

Termopar, afinal o que é?

O termopar é um dos mais importantes sensores utilizado na medição de temperatura. nos mais variados segmentos industriais.

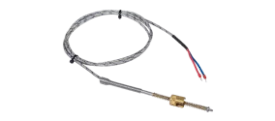

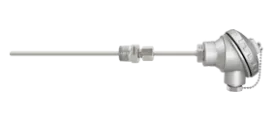

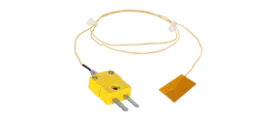

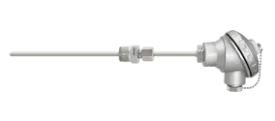

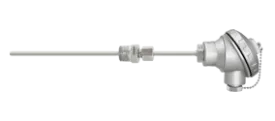

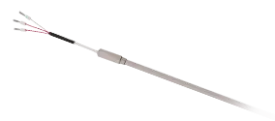

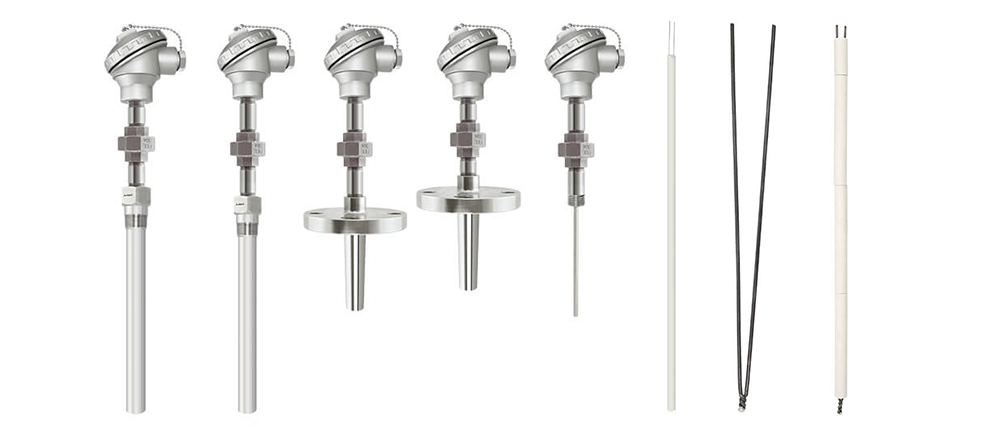

Thermocouples are simple, robust and low-cost temperature sensors used in a wide range of processes since their measurement capacity can be applied to a wide temperature range.

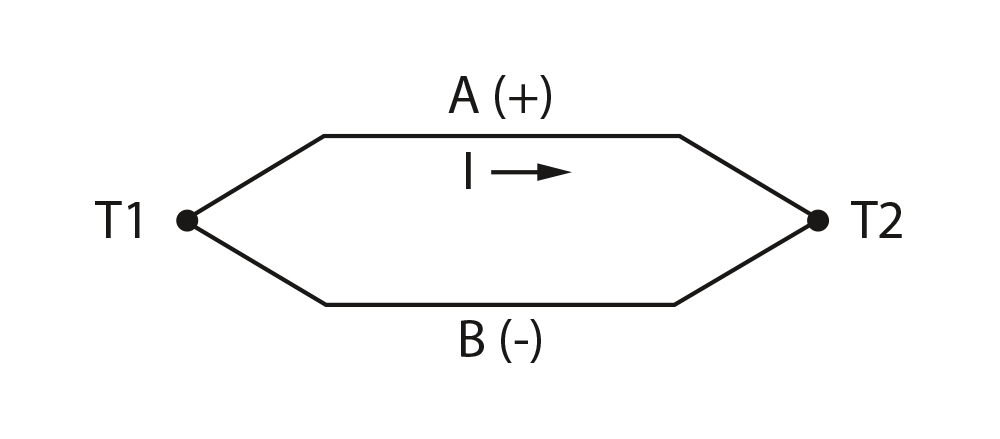

Constituído por dois metais distintos, unidos na suas extremidades e conectados a um termômetro termopar ou outro dispositivo com capacidade termopar, formam um circuito fechado que gera uma força eletromotriz quando as duas junções (T1 e T2) são mantidas a temperaturas diferentes.

Alutal is now recognized as the leading thermocouple manufacturer in Brazil, producing sensors according to your design, thus ensuring that they are 100% suitable for measuring your process.

Conheça mais sobre os princípios físicos dos termoelementos em nossa Wiki:

Efeito Seebeck

A reação elétrica foi descoberta por acaso, no ano de 1821, pelo físico estoniano Thomas Seebeck.

Quando ele notou que, em um circuito fechado, formado por dois condutores distintos A e B, ocorre uma circulação de corrente enquanto existir uma diferença de temperatura DT entre as suas junções.

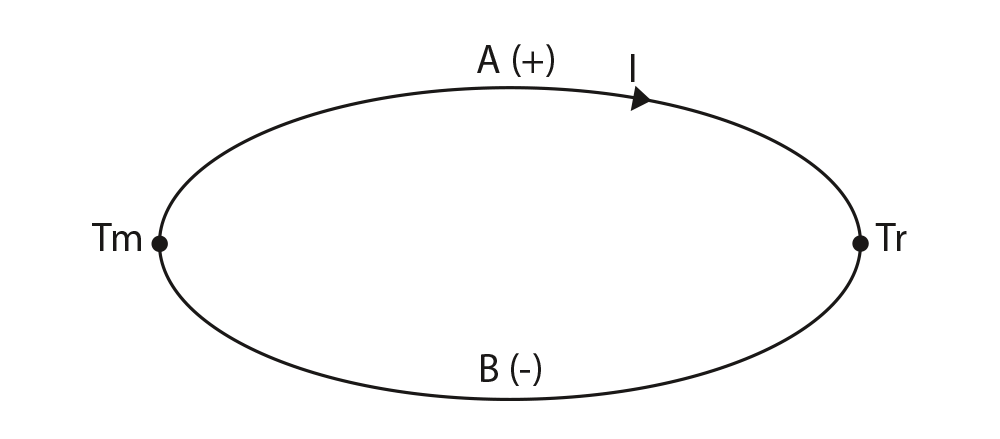

We call the measuring joint Tm, and the other, the reference joint Tr. The existence of a thermal emf AB, in the circuit, is known as efeito Seebeck.

Sempre que a temperatura da junta de referência é mantida constante, verifica-se que a f.e.m. térmica é uma função da temperatura Tm da junção de teste, assim, este fato permite utilizar um par termoelétrico como um termômetro.

Tipos de Termopar

Estão disponíveis em vários tipos ou calibrações, é importante selecionar com cuidado o termopar adequado para a sua aplicação.

The table below lists the main types of termopares :

| Calibração | Elemento Positivo | Elemento Negativo | Faixa de Temperatura Usual | Linha de Erro Standard (Escolha o Maior) | Linha de Erro Especial (Escolha o Maior) |

|---|---|---|---|---|---|

| Tipo T | Cobre | Constantan | -200°C~0°C | +/-1°C ou +/-1,5% | --/-- |

| Tipo T | Cobre | Constantan | 0°C~370°C | +/-1°C ou +/-0,75% | +/-0,5°C ou +/-0,4% |

| Tipo J | Ferro | Constantan | 0°C~760°C | +/-2,2°C ou +/-0,75% | +/-1,1°C ou +/-0,4% |

| Tipo E | Cromel | Constantan | 0°C~870°C | +/-1,7°C ou +/- 0,5% | +/-1,0°C ou +/-0,4% |

| Tipo K | Cromel | Alumel | 0°C~1260°C | +/-2,2°C ou +/- 0,75% | +/-1,1°C ou +/-0,4% |

| Tipo N | Nicrosil | Nisil | 0°C~1260°C | +/-2,2°C ou +/- 0,75% | +/-1,1°C ou +/-0,4% |

| Tipo S | 90% Platina / 10% Rhódio | Pt 100% | 0°C~1480°C | +-1,5°C ou +/- 0,25% | +/-0,6°C ou +/-0,1% |

| Tipo R | 87% Platina / 13% Rhódio | Pt 100% | 0°C~1480°C | +/- 1,5°C ou +/- 0,25% | +/-0,6°C ou +/-0,1% |

| Tipo B | 70% Platina / 30% Rhódio | 94% Platina / 06% Rhódio | 870°C~1700°C | +/- 0,5% | +/-0,25% |

Termopar Tipo B

Apresenta características muito parecidas com as dos modelos R e S. Eles são mais estáveis, contudo, devido à sua reduzida sensibilidade, costumam ser utilizados apenas para medir temperaturas acima dos 300°C, até os 1800°C.

Também pode ser adequado para uso no vácuo por curtos períodos. No entanto, ele não deve ser usado em atmosferas redutoras ou que contenham vapores, tanto metálicos quanto não metálicos. Esse equipamento não deve ser inserido diretamente num tubo de proteção primário metálico, e requer a utilização de isoladores e tubos de proteção cerâmicos de alta alumina.

Termopar Tipo E

Pode ser utilizado em atmosferas oxidantes, inertes ou vácuo. Contudo, não é indicado para atmosferas alternadamente oxidantes e redutoras.

Em comparação com outros termopares usualmente utilizados, possui maior potência termoelétrica – algo bastante vantajoso para quem deseja detectar pequenas variações de temperatura.

Termopar Tipo J

Pode ser utilizado em atmosferas redutoras, neutras ou oxidantes. Contudo, não é recomendado em atmosferas com alto teor de umidade e também em baixas temperaturas, pois o termoelemento JP pode se tornar quebradiço.

Termopar Tipo K

Se destaca por ser de uso genérico. Ele possui um baixo custo, e por sua popularidade está disponível nas mais diversas sondas. As temperaturas cobertas por esse produto variam entre -200°C e 1200°C.

Termopar Tipo N

Its high stability and resistance to oxidation at high temperatures makes it more suitable for measurements at high temperatures, without resorting to thermocouples that incorporate platinum in their construction (types B, R and S). It was designed to be an “evolution” of the K type.

Termopar Tipo S

Pode ser utilizado em atmosferas inertes ou oxidantes. Ele apresenta um bom índice de estabilidade quando exposto a altas temperaturas ao longo do tempo, se destacando por ser superior à dos termopares não constituídos de platina.

Porém, os termoelementos desse aparelho não devem ficar expostos a atmosferas redutoras ou então com vapores metálicos. O indicado é que eles jamais sejam inseridos diretamente em tubos de proteção metálicos, mas primeiramente num tubo de proteção cerâmico com as seguintes especificações: fabricado com alumina (Al2O3) de alto teor de pureza (99,7%), comercialmente denominado tipo 799 (antigo 710).

Contudo, vale ressaltar que existem disponíveis no mercado tubos cerâmicos com teor de alumina de 67%, denominados tipo 610, mas sua utilização para termopares de platina não é recomendável.

Termopar Tipo T

É indicado para atmosferas inertes, oxidantes ou redutoras. Ele conta com uma boa precisão por conta de uma grande homogeneidade com que o cobre pode ser processado.

Nas temperaturas acima de 300° C, a oxidação do cobre se torna muito intensa, reduzindo, então, sua vida útil e provocando desvios em sua curva de resposta original.

Termopar Tipo R

They have the same characteristics as type S thermocouples, being suitable for measuring temperatures up to 1600 °C, however, due to their higher cost, their use in industry in general is not as common.

Qual a diferença entre termopar e termorresistência?

There are two very common thermoelements for measuring temperature: Termopares e termoresistências . Apesar dos nomes parecidos, cada um deles tem suas próprias características e funcionamentos.

Os termopares transformam energia térmica em energia cinética e são adequados para temperaturas elevadas até 1700°C, apresentam baixo custo e são utilizados nos mais variados processos e em amplas faixas de temperatura.

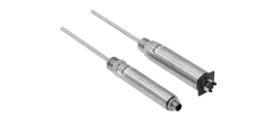

Enquanto as termoresistências são sensores de alta precisão e boa repetibilidade de leitura, baseados no princípio da variação da resistividade elétrica de um metal em função da temperatura.

Geralmente a termorresistência é feita de platina, mas também podem ser utilizados outros materiais, como por exemplo o níquel e sua faixa de utilização vai de -200ºC a 650ºC.

As principais diferenças entre eles são:

| Termopar | Termoresistência |

|---|---|

|

|

Conheça as 5 principais vantagens do Termopar sobre a Termorresistencia (RTD)

- Custo menor quando comparado com RTD na mesma faixa

- Range de temperatura maior do que as termorresistências

- Melhor tempo de resposta

- Mecanicamente mais robusto

- Pode ser utilizado em locais com muita vibração

Como escolher o sensor de temperatura correto?

É fundamental que seja corretamente especificado respeitando a sua aplicação.

Using sensors with inappropriate characteristics can lead to measurement errors, process failures and short service life.

Assista ao vídeo abaixo para descobrir qual o melhor termopar:

Nossos engenheiros destacam 5 pontos que a serem observados:

- Determinar em detalhes a aplicação onde será instalado

- Analisar cuidadosamente a variação de temperatura existente no local que o termopar será exposto

- Avaliar cuidadosamente qualquer resistência química que o termopar será exposto durante seu funcionamento

- Considerar a necessidade de abrasão e/ou resistência a vibração

- Criar uma lista com todos os requisitos de instalação (observar a compatibilidade com o equipamento existente; orifícios existentes podem determinar o diâmetro da sonda, etc)

Importancia da calibração dos sensores de temperatura

Tão importante quanto a escolha do sensor adequado é a sua devida calibração.

É através dela que podemos validar se o instrumento corresponde entre uma grandeza física conhecida ou padronizada e as suas leituras.

A calibração deve seguir padrões de mercado como a Acreditação RBC da CGCRE (Coordenação Geral de Acreditação), ABNT NBR ISO/IEC 17025, entre outras.

Descubra quanto custa 1°C de variação em combustível no seu processo

Você já parou pra pensar o quanto custa 1°C dentro do seu processo?

Quanto de combustível, energia você gasta financeiramente para aquecer ou resfriar o seu processo ao longo de 1 ano?

Os engenheiros calculistas da Alutal, desenvolveram um poderoso algoritmo que com base nas variáveis do seu processo (como tipo de material, combustível, poder calorífico, etc.) calcula e entrega um relatório exclusivo demonstrando o custo de 1ºC na sua empresa em 1 ano.

acessar relatório agoraVeja abaixo os termopares fabricados pela Alutal

Quer conhecer mais sobre a teoria e mecânica de funcionamento dos termopares?